How to Optimize Material Selection: Criteria, Methods, and Software for R&D

Faced with a market offering more than 160,000 products, an engineer’s intuition can no longer be relied upon as a reliable decision-making tool. Never before has innovation benefited from such a wealth of materials, but choosing the right materials has never been so challenging. The growing amount of data available on material properties and performance creates an abundance of information which, without a rigorous method, quickly turns into decision paralysis.

In this context, relying on experience alone is no longer sufficient: choices influenced by bias or habit can lead to the selection of unsuitable materials and compromise a project. Modern engineers must now identify the optimal solution using high-performance material selection software capable of transforming market complexity into a strategic advantage. How can this wealth of data be converted into a lever for differentiation and competitiveness?

The Strategic Shift: From Intuition to Data-Driven Material Selection

The proliferation of processes and the advent of advanced technologies such as CAD/CAM have greatly expanded the range of possibilities, but this wealth of options now makes every design decision more sensitive and interdependent. For R&D engineers, every choice creates a cascade of effects: adjusting one material parameter means redesigning the entire balance of the system.

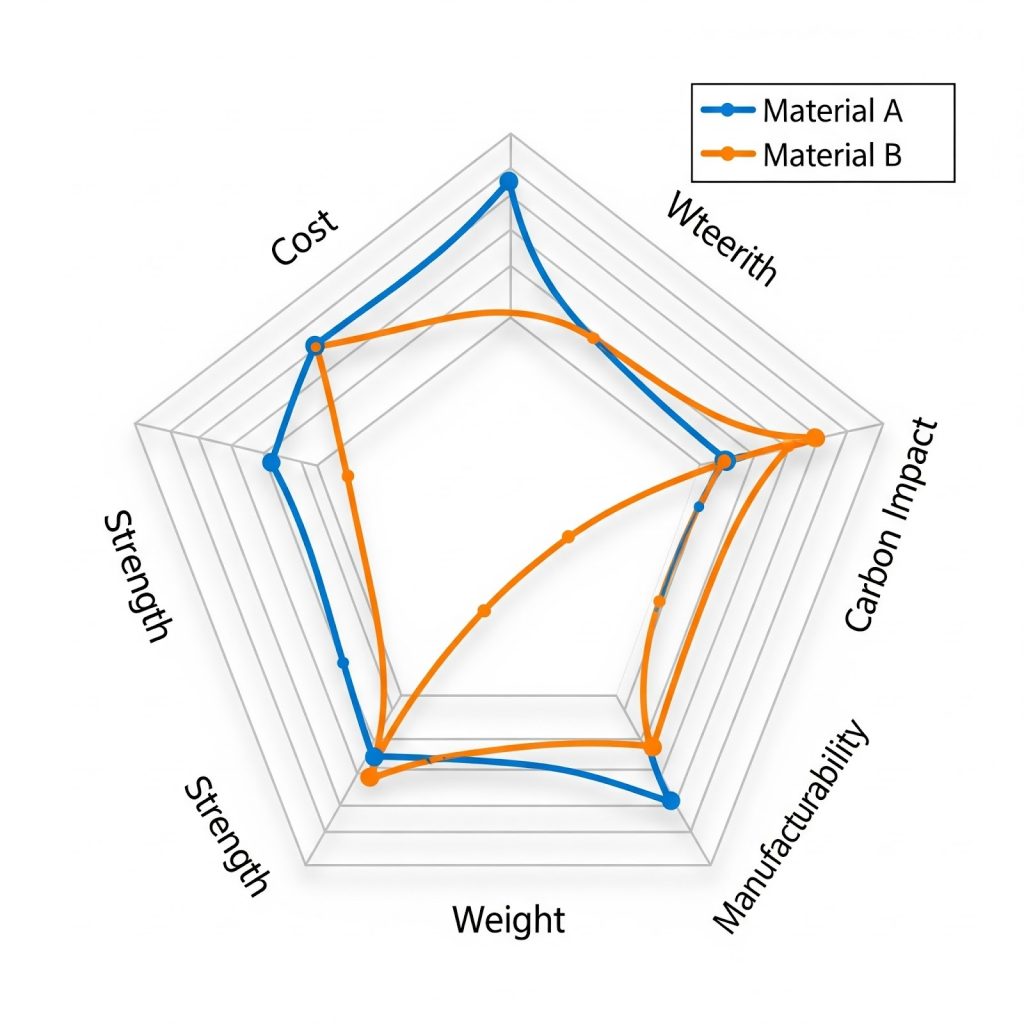

The central challenge is therefore to arbitrate between sometimes conflicting requirements. A detailed analysis of the decision criteria reveals three essential levers:

- Management of Subjective Factors: The choice often oscillates between aesthetic objectives driven by design and durability requirements dictated by engineering.

- Mastering Physical Trade-offs: Identifying the right performance indicators makes it possible to precisely quantify a behavior (e.g., elasticity) in relation to a given constraint (e.g., minimum mass).

- Predictability of Results: Ensuring success requires a systematic approach based on a robust decision-making framework that guarantees consistency of choices throughout the development cycle.

This diagnostic approach is essential for isolating the parameters that can truly be optimized. The time for empirical decisions is over: today’s complexity requires a rigorous methodology, supported by materials software capable of orchestrating and objectifying each step of the process.

Why Has Material Selection Become a Strategic Engineering Challenge?

In an increasingly demanding industrial environment, material selection goes far beyond simple economic evaluation: it has become a strategic exercise that brings together mechanical constraints, aesthetic considerations, manufacturing requirements, and sustainability imperatives. As several technical analyses have pointed out, this process is akin to a system of tensions, in which each parameter adjustment redistributes the overall balance of the product and modifies its final performance.

How to Manage Subjective Bias in Material Selection

One of the recurring pitfalls for R&D teams is taking individual preferences into account. Studies show that subjective factors (whether a designer’s intuition or a technician’s habits) can lead to the selection of an unsuitable material if these criteria are not guided by a rational methodology.

It is not uncommon, for example, for an operator to favor the material they know best, to the detriment of a more effective solution. These biases automatically increase the risk of failure, as a non-objective choice ignores the truly relevant material properties (mechanical strength, thermal resistance, fatigue behavior, etc.).

Since no material is universal, each selection requires a rigorous, case-by-case evaluation based on measured performance rather than impressions. Only a structured approach can effectively balance constraints and expectations and ensure a sound technical decision.

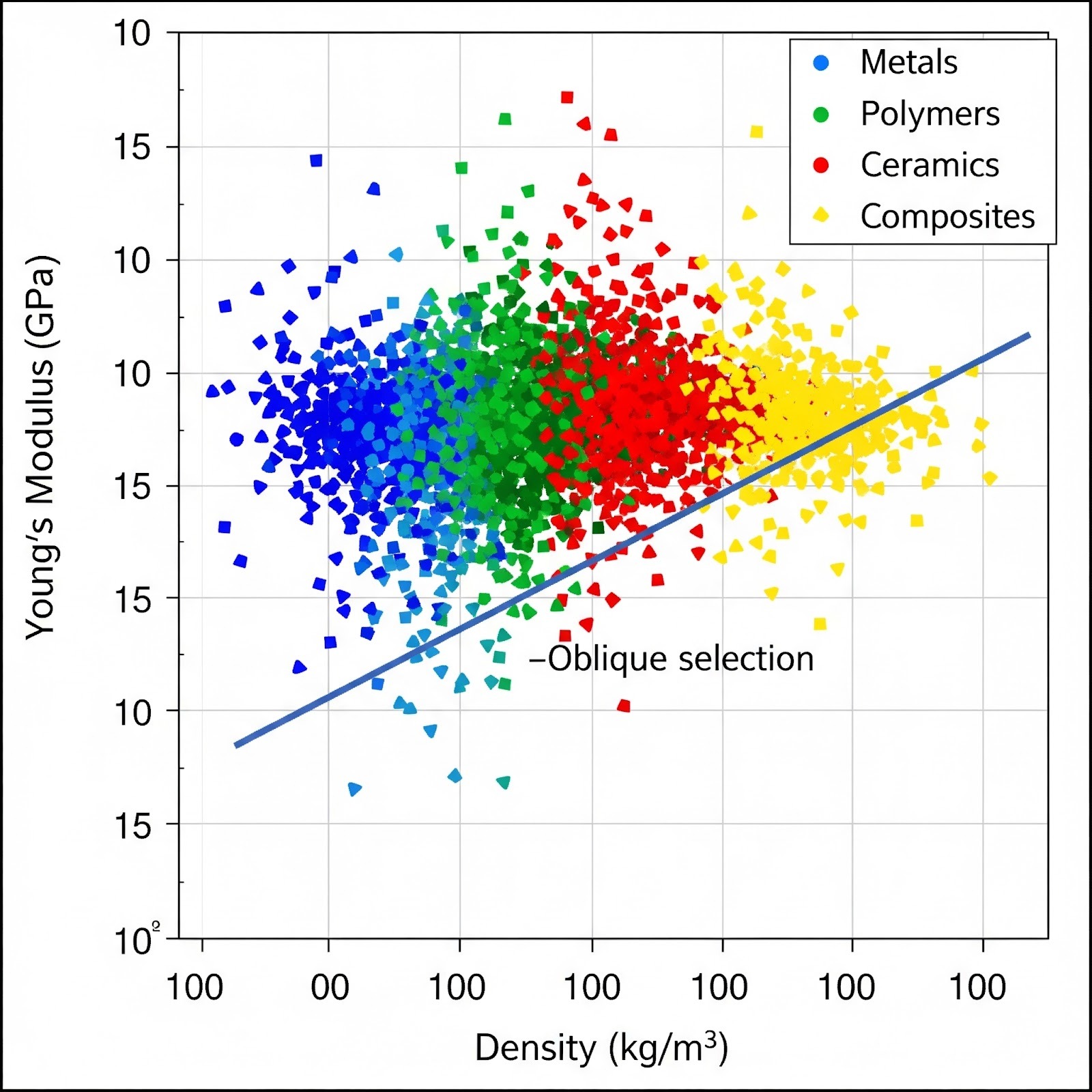

The Ashby Method: A Methodology to Rationalize Material Properties

To overcome the limitations of intuitive decision-making, a rigorous scientific approach is required. The systemic approach developed by Michael F. Ashby provides precisely this framework: it converts functional specifications into measurable criteria, enabling objective comparison of material properties and the gradual elimination of irrelevant options.

Use Diagrams to Define Your Material Performance Indicators

At the heart of the method, logarithmic scale diagrams structure all material properties in order to guide rational choice. The goal is clear: to identify the material capable of performing the required function, under stress, with minimal induced degradation.

This approach is based on a methodical three-step process:

- Define the Performance Index: The engineer calculates a relevant ratio (e.g., stiffness/mass), transforming the functional requirement into an objective criterion. This index ranks material families according to their actual suitability.

- Visualize Using Selection Lines: Materials located on the same line have equivalent behavior; those positioned above exceed the set requirements. This visual reference radically simplifies comparative analysis.

- Integrate the Shape Factor: The choice of materials does not depend solely on the material itself. The geometry (tube, beam, solid cylinder) completely changes the structural performance. Integrating the shape factor therefore allows the function to be optimized even before the final selection.

- Consider the Processes: Manufacturing processes directly influence the final performance; it is therefore essential to integrate them into the analysis to ensure consistency between the theoretical choice and industrial reality.

How Dedicated Material Selection Software Transforms Your R&D Process

The digital transformation of engineering means that manual sorting approaches are no longer sufficient. With thousands of references available, adopting dedicated material selection software is essential to secure the design and guarantee the robustness of technical choices.

Why Do Spreadsheets Limit Your Material Selection Capacity?

The explosion of data makes careful handling essential to avoid information overload. Where spreadsheets quickly reach their limits when mechanical, chemical, or process constraints need to be cross-referenced, materials software provides intelligent structuring capable of absorbing this complexity.

The use of a dedicated tool radically transforms the engineering workflow:

- Structured Centralization: The platform brings together all relevant data (physical properties, chemical characteristics, manufacturing processes) in a single repository, eliminating data dispersion.

- Conflict Management: The system allows you to immediately visualize the impact of a change in one variable on other material properties, providing a systemic understanding of technical trade-offs.

- Guaranteed Objectivity: Thanks to a transparent decision-making matrix, the solution eliminates subjective bias and facilitates the selection of the optimal material based on quantified and verifiable criteria.

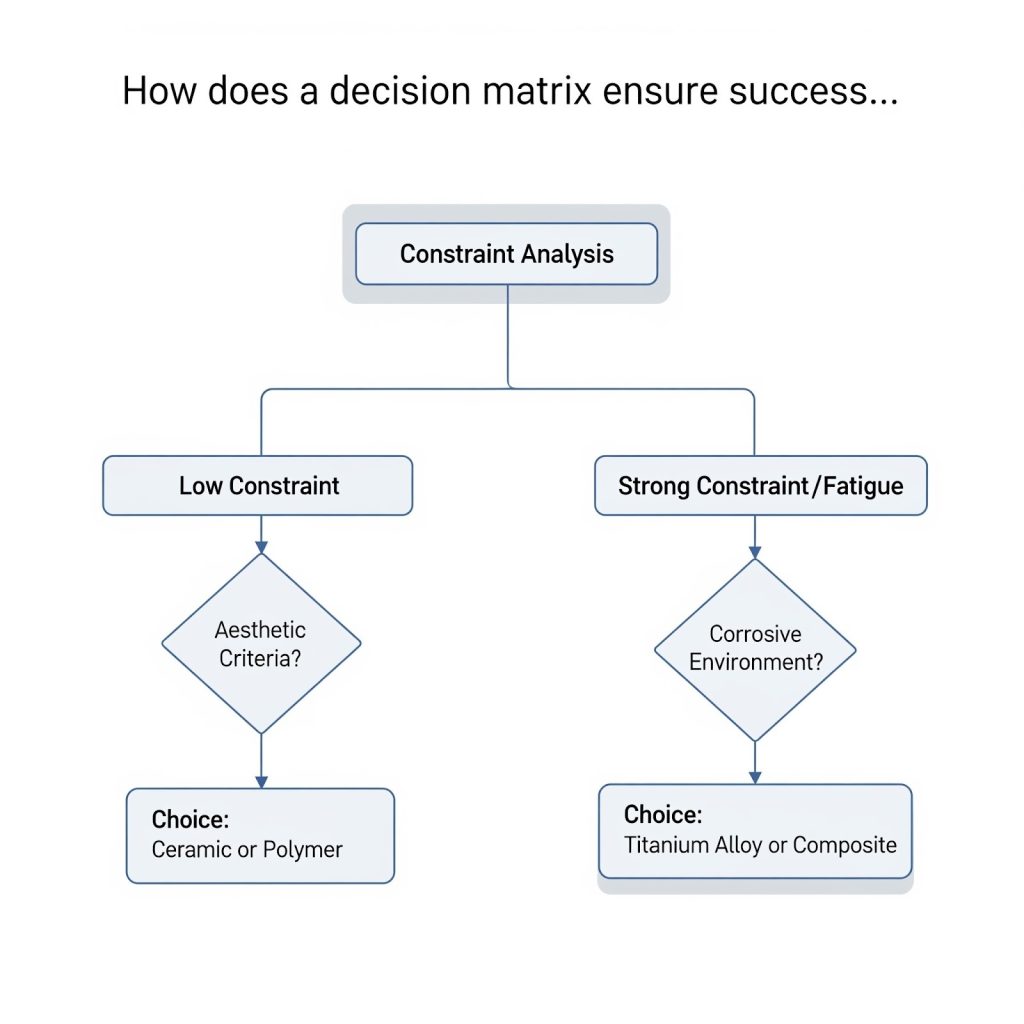

Case Study and Analysis: The Importance of the Decision Matrix

To fully understand the value of methodical material selection, the analogy with prostheses is illuminating: just like a heavily used mechanical part, they must withstand repeated, variable, and sometimes extreme loads. Long-term performance therefore depends less on the “most robust” material than on the consistency between its properties and its context of use.

Ensuring Success Through Multi-Criteria Analysis

Clinical studies show that the same level of stability can be achieved with radically different materials (ceramic or metal) provided that the choice of materials is aligned with the mechanical scope. Endurance statistics reveal trends that are perfectly transferable to structural engineering:

- Low Stress Context (unit element): 5-year survival rates are almost identical (95.6% for metal, 95.4% for ceramic), demonstrating that both options are mechanically viable.

- High-Stress Context (long-span structure): As the span increases (equivalent to a bridge or beam), material sensitivity becomes a determining factor: ceramic survival rates fall to 89.6% compared to 94.4% for metal.

This study highlights a fundamental rule: only a multi-criteria analysis can identify the material that meets the maximum number of requirements. The decision matrix is therefore not a theoretical tool, but a guarantee of a reliable and sustainable technical compromise for any project.

Towards Software-Assisted Materials Engineering

In any engineering discipline, we must abandon the idea of a universal material. The final performance is always the result of a controlled compromise between functional properties, processes, and usage constraints. The challenge is therefore not to find a hypothetical “super-material,” but to structure the decision using a rational approach.

Whether using Ashby diagrams or material selection software, these approaches have a common goal: to transform a complex set of data into an objective and predictive decision. For R&D teams, these tools are becoming indispensable for securing choices early in the development process.

Before launching the first prototype, one question must be asked: are your material selection criteria based on a traceable and reproducible analysis… or on tacit habits?

TEEXMA for Materials: Centralizing Data and Securing R&D

While the challenges of complexity and data overload are universal, TEEXMA for Materials offers a dedicated platform that directly addresses the limitations of spreadsheets and generic databases. Designed specifically for engineering data, TEEXMA acts as a secure, centralized repository for all your material properties, supplier data, and historical test results. It natively supports the application of multi-criteria decision matrices, allowing engineers to visualize trade-offs instantly, apply the principles of the Ashby method systematically, and ensure every material choice is traceable, verifiable, and free from subjective bias.