Herausforderungen

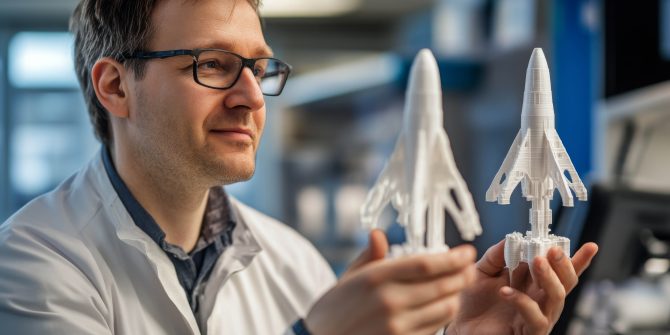

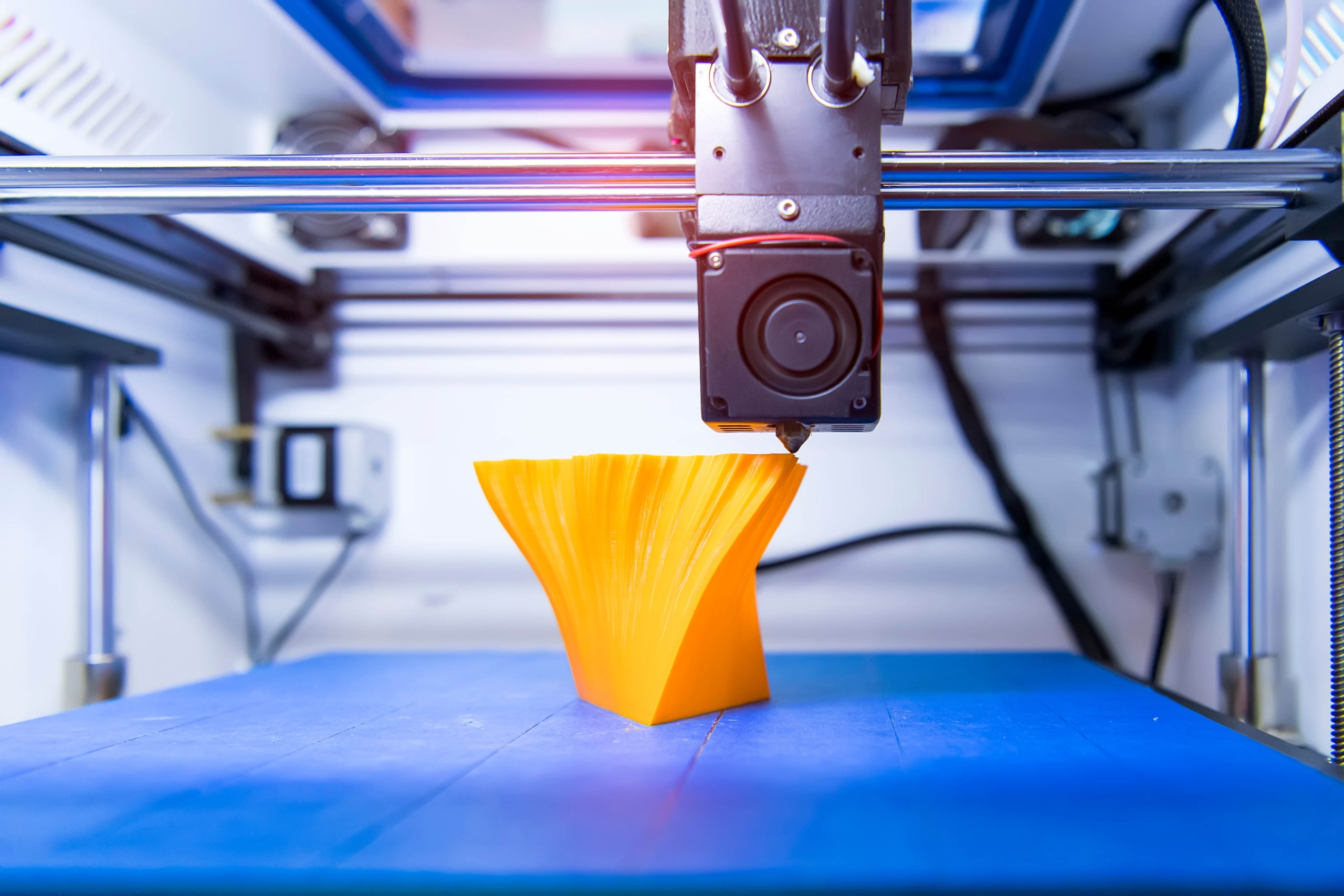

In einem sich ständig weiterentwickelnden Umfeld der additiven Fertigung müssen sich Ingenieure und Produktionsleiter immer komplexeren Herausforderungen stellen. Die Koordination der verschiedenen Akteure innerhalb eines Projekts ist ebenso wichtig wie die sorgfältige Verwaltung der Verbrauchsmaterialien. Die Aufrechterhaltung eines Qualitätsniveaus, das über dem der traditionellen Herstellung liegt, wird zu einer unumgänglichen Anforderung. Die Rückverfolgbarkeit von Daten ist entscheidend, um die Konformität und Integrität von Prozessen zu gewährleisten und gleichzeitig das Finanzmanagement von Projekten zu optimieren.

Die Herausforderungen in Bezug auf die Qualität der fertigen Teile werden durch immer strengere Normen noch verschärft. Ingenieure und Designer müssen sich in einem Umfeld bewegen, in dem jedes Detail zählt, von der Auswahl der Materialien bis hin zur Produktvalidierung. In diesem Zusammenhang ist eine geeignete Lösung ein strategischer Vorteil. Durch die Integration leistungsfähiger Tools für die Verwaltung von Rückverfolgbarkeit, Qualität und Materialmanagement können Unternehmen ihre additiven Fertigungsprojekte sichern und ihre Effizienz steigern. Dies ist eine Notwendigkeit, um die aktuellen Herausforderungen zu bewältigen und die Zukunft der Produktion vorzubereiten.