Enjeux d'un logiciel de Fabrication Additive

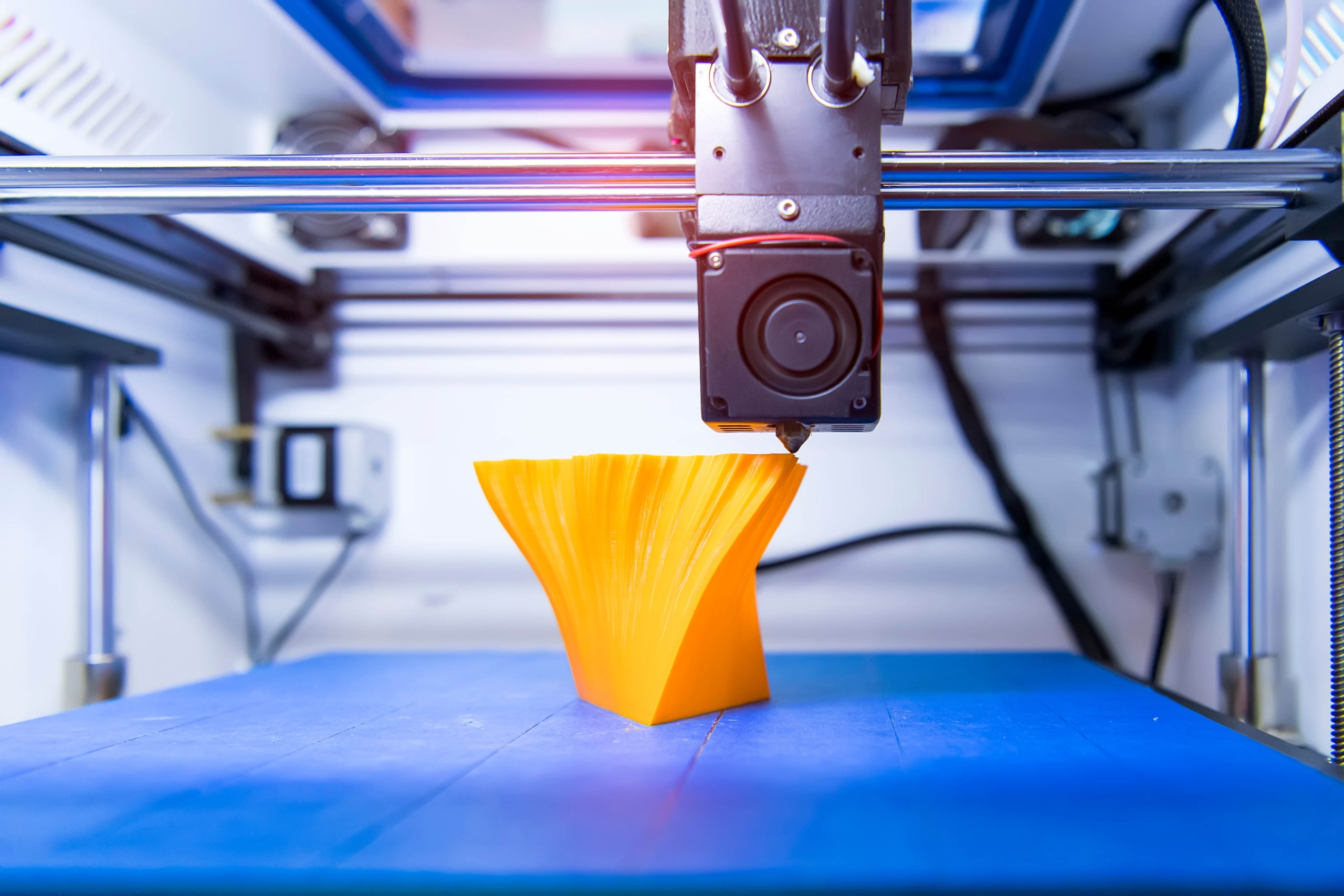

Dans un contexte de fabrication additive en constante évolution, les ingénieurs et responsables de production doivent faire face à des défis de plus en plus complexes. La coordination de divers acteurs au sein d’un même projet est essentielle, tout comme la gestion rigoureuse des consommables. Maintenir un niveau de qualité supérieur à celui de la fabrication traditionnelle devient une exigence incontournable. La traçabilité des données s’avère cruciale pour garantir la conformité et l’intégrité des processus, tout en optimisant la gestion financière des projets.

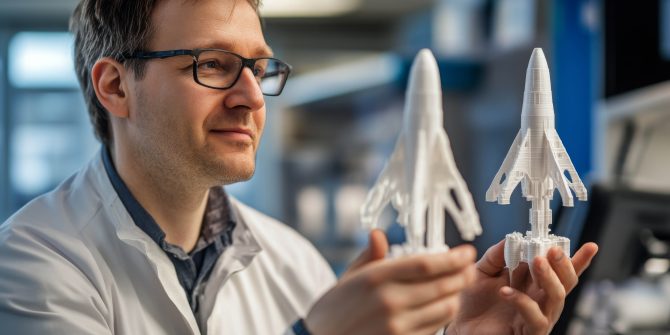

Les enjeux liés à la qualité des pièces finies sont également renforcés par des normes de plus en plus strictes. Les ingénieurs et designers doivent naviguer dans un environnement où chaque détail compte, depuis la sélection des matériaux jusqu’à la validation des produits. Dans ce contexte, une solution adaptée se présente comme un atout stratégique. En intégrant des outils performants pour gérer la traçabilité, la qualité et la gestion des matériaux, les entreprises peuvent sécuriser leurs projets de fabrication additive et améliorer leur efficacité. C’est une nécessité pour faire face aux défis actuels et préparer l’avenir de la production.